SOLUTIONS

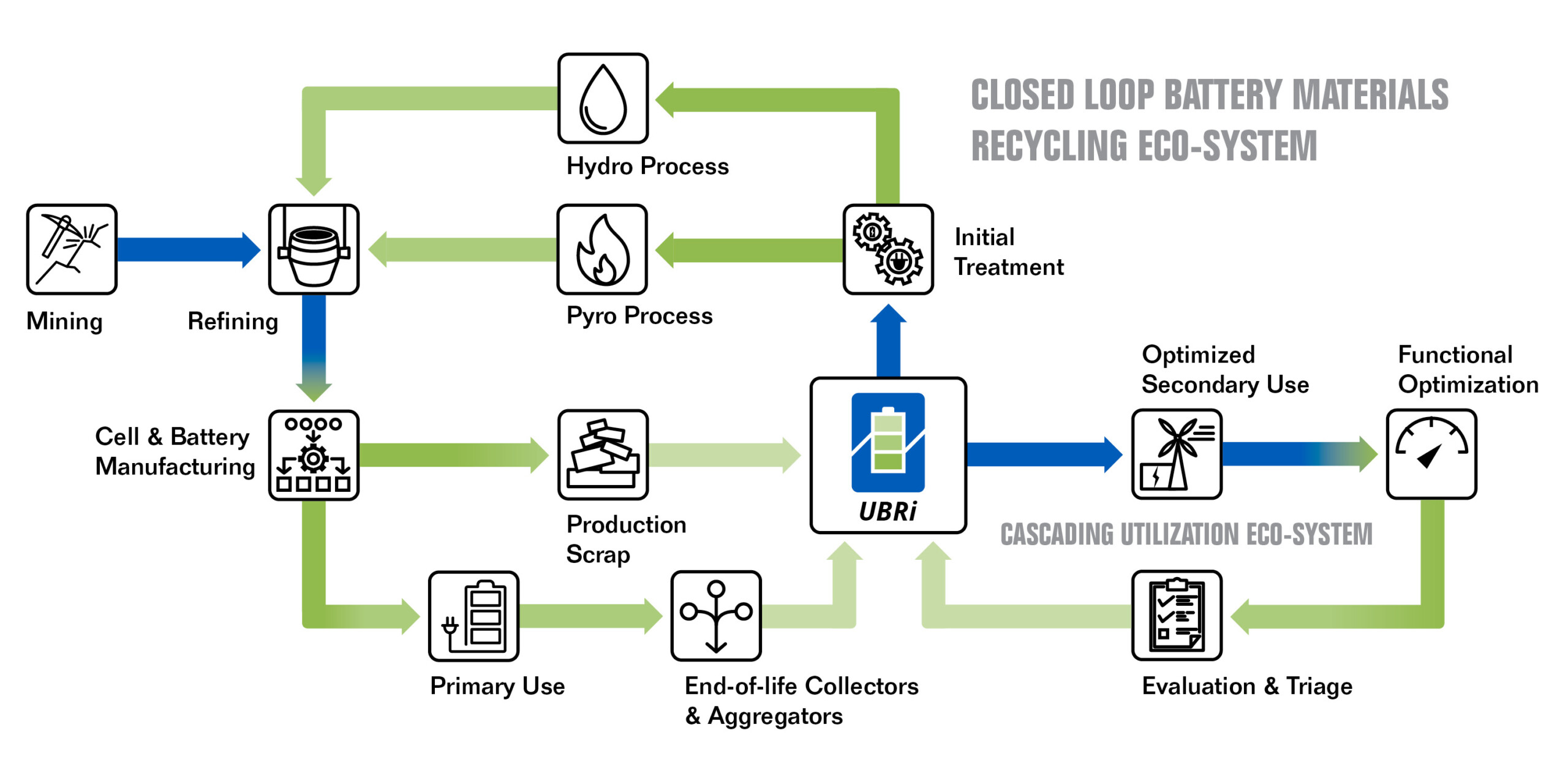

UBRi optimizes and facilitates critical closed-loop solutions in the battery recycling eco-system

UBRi helps clients across the battery ecosystem manage the risks and address the challenges they face in securing environmentally and economically sustainable recycling solutions

UBRi Recycles All Types Of Batteries And Battery Materials

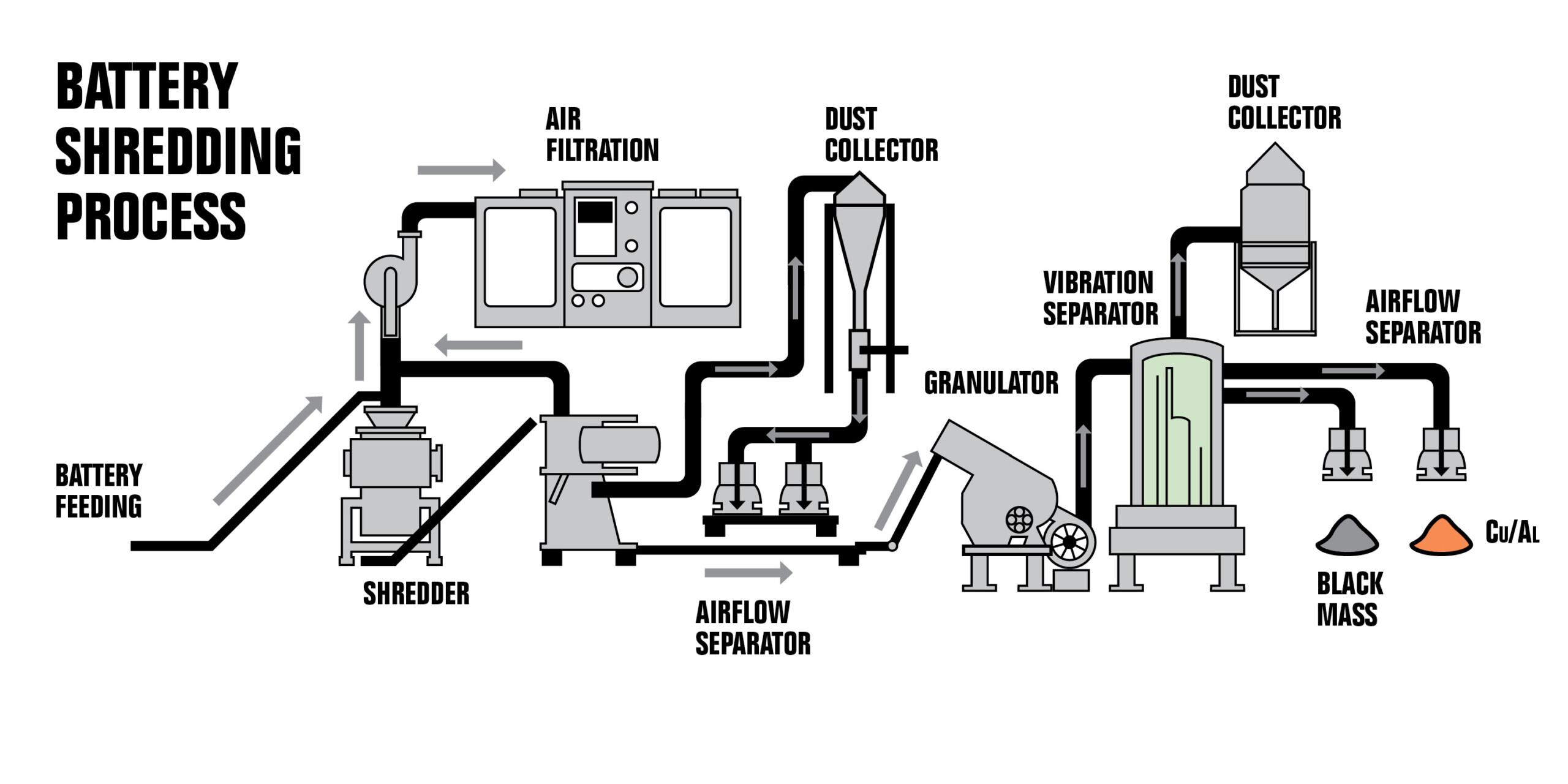

BLACK MASS

Output from the crushing/treatment process

HOUSEHOLD BATTERIES

As used in common household applications, e.g. D, C, AA, etc

INDUSTRIAL BATTERIES

As used in wireless devices, long-lifecycle applications

VEHICLE BATTERIES

As used in electric and hybrid electric cars

ELECTRONIC STORAGE SYSTEMS

As used in capacitor- and magnetic-based systems

PORTABLE CHARGEABLE BATTERIES

As used in laptops, eBikes, power tools, etc.

BATTERY PERIPHERALS & ACCESSORIES

As used with controllers and chargers

PRODUCTION SCRAP

Excess or unusable materials generated in battery production

Excess or unusable materials generated in battery production

PACKAGING & TRANSPORTATION MANAGEMENT

BATTERY SORTING BASED ON CHEMISTRY & OTHER CRITERIA

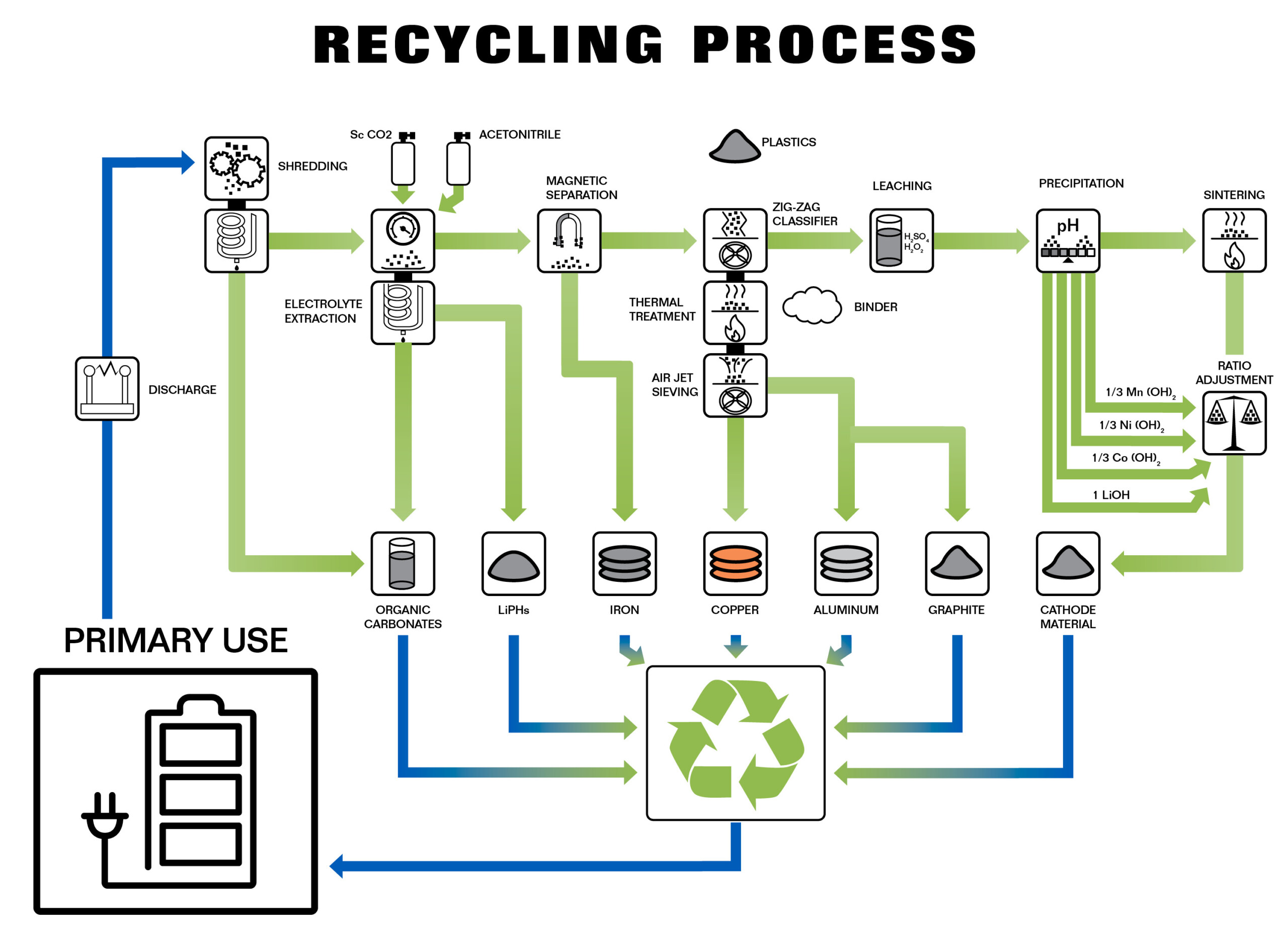

SHREDDING & REFINERY FOR MATERIALS RECOVERY

COMPLIANCE, RECYCLING, POST-RECYCLING & RECOVERY RATES